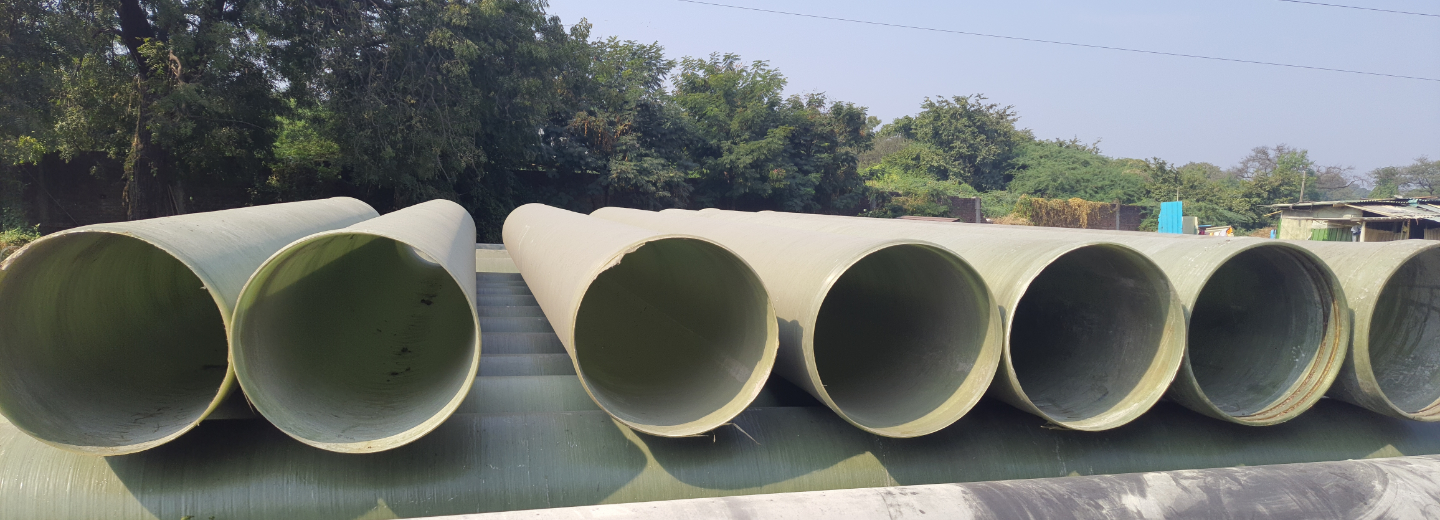

FRP / GRP Pipes

Satyam Composite Fiberglass is manufacturer of FRP / GRP Pipes & Fittings.

Our pipes are manufacturing by automated CNC Machine by Dual Helical Filament Winding Process Method. We use mechatronic technology that is employed to provide high degrees of reliability and flexibility.

Satyam Composite Fiberglass is design, development, manufacturing and installation of FRP / GRP pipes and fittings.. We also provide consultancy services for special projects.

FRP / GRP Pipes Standards & Codes:

IS 12709, IS 14402, AWWA C950, AWWA M45, DIN, ASTM D 2996, ASTM D 3517, ASTM D 3262, ASTM D 4161, ASTM D5421, ASTM D 3754, BS 5480:1990, BS EN 1796:2006, BS EN 14364:2006, ISO 14692:2002 and many other International Standards are applicable.

FRP / GRP Pipes Process:

Standard pipe manufacturing using Dual Helical Filament Winding process in which the fiber glass roving is wetted with resin and is wound on steel mandrel / FRP mandrel / wooden mandrel at precalculated winding angles. The dual helical winding pattern is responsible for providing the composite product with maximum mechanical durability.

Chemical Barrier / Liner Layer:

The inner-most layer mostly impregnated with Unsaturated Polyester Resin (90%) to provide maximum chemical resistance. The resin used will decide the extent of its chemical and temperature resistance.

Mechanical Barrier / Structural Layer:

The structural wall is generally 70% glass and 30% resin providing it the optimum mechanical strength. The entire process is controlled via software in which we determine the winding angles as well as the number of layers to be wound on to the product.

Use of ovens help in fastening the curing process and also makes sure the bonding takes place well. Once the pipes are extracted, they are calibrated at the ends if required (flexible joint).

Final Barrier / Outer Layer:

The outer layer mostly impregnated with Unsaturated Polyester Resin Rich Coat along with U. V.

Inhibitor for the U.V. Protection along with good esthetic look.

FRP / GRP Pipes Sizes:

Our Production Range include FRP / GRP Pipes of diameter 100 mm to 2200 mm.

Pressure Class:

Pipes and fittings are classified according to the Nominal pressure. Standard pressure classes are 3,6,9,12,15. Intermediate and higher pressure classes are considered on request or depending on the design condition.

Stiffness Class:

Pipes are also classified according to specific pipe stiffness. Standard stiffness classes are 1250, 2500, 5000 and 10000 N/m2 . Intermediate of higher stiffness classes are available on request or depending on the design condition.

Standard Length:

The standard length of pipe is 3 Mtr / 6 Mtr / 9 Mtr / 12 Mtr (As Per Indian Standard)

5.5 Mtr / 11.5 Mtr (For Export – Suitable to Containers).

Joint Types:

- PL/PL: Plain end/Plain End lamination joint

- SO/SP: Socket Spigot flexible joint

- FL/FL: Flanged / Flanged joint

FRP / GRP Pipes Tests:

Satyam Composites Fiberglass is equipped with a full fledged Quality Control Laboratory. All the

incoming raw material and finished products are subjected to various tests to ensure that only good

quality pipes and fittings and delivered. Some of the tests performed are given below.

Type tests:

- Strain corrosion test

- Hydrostatic Design Basis

- Long term stiffness

Test on Finished products:

- Hydrostatic pressure test

- Stiffness test

- Axial tensile strength test

- Hoop tensile (burst) strength test

- Curing test – Barcol hardness

- Loss on ignition test

- Visual inspection and Dimensional control

- Joint tightness test

- Impact resistance

Test on Raw Materials:

Resin

- Reactivity and Viscosity

- Solid contents

Glass

- Texture

- Moisture content

- Loss on ignition

Application of FRP / GRP Pipes & Fittings:

Generally this products are used in the below sectors:

Distribution System: Sea Water, Potable Water, Irrigation, Cooling Tower etc.

Sewerage System: Sanitary Sewage, Drainage, Industrial, Effluent Waste etc.

Industrial System: Desalination, Power Generation, Petrochemical, Oil and Gas, Other production

plants etc.

Benefits of FRP / GRP Pipes & Fittings:

- Long Life

- Cost Effective

- Light Weight

- Easy to Install

- Dimension Stability

- Very Low Friction Factor (Saving Pumping Cost)

- Low Maintenance

- Corrosion Resistance

- Smooth Inside Finish

- Compatibility

- Fire Resistance